Alfred University acquires nanoindentation equipment used to study material properties

The Inamori School of Engineering at Alfred University has acquired a state-of-the-art piece of equipment researchers will use to characterize various mechanical properties of materials ranging from hard alloys to soft biomaterials.

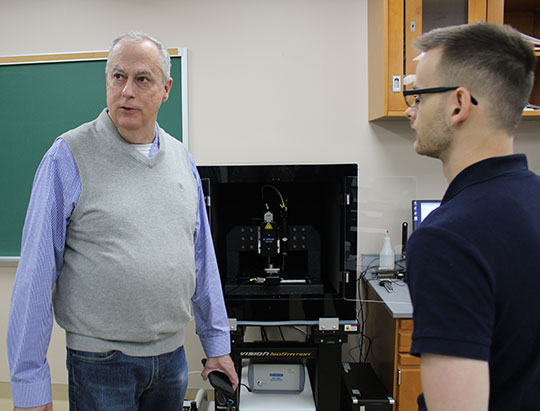

Semilab, an international company based in Budapest, Hungary, and a leading manufacturer of precision measurement solutions, has loaned one of its IND-1500 nanoindenters to the University. On Wednesday, representatives of Semilab were on hand to demonstrate and provide training on the equipment.

“The nanoindenter adds to the growing suite of advanced mechanical testing equipment at Alfred University,” commented John Simmins ’84, PhD ’90, executive director of the Center for Advanced Ceramic Technology (CACT) at Alfred University. “It will allow for both basic and applied research and is another example of Alfred leading the way in the study of ceramics and glass.”

Alfred University alumnus John Byrnes ’04, North American sales manager for Semilab, was among a group of his company’s representatives who gave a presentation on Semilab’s products in general and nanoindentation technology in particular. The IND-1500 will be housed in the McMahon Engineering Building and be used to assist in research and instruction by faculty, technicians, and students in the Inamori School of Engineering.

Byrnes, who earned a bachelor’s degree in electrical engineering from Alfred University, has been with Semilab for 16 years. He described nanoindentation as “a way of measuring the mechanical properties of thin films and bulk materials.” This is done by applying force to a diamond tip onto a material, which allows for the measurement of the material’s mechanical properties, such as hardness, elasticity, viscoelasticity.

Nanoindentation testing—which assesses properties of bulk materials, composites, nanostructured materials, thin films, and coatings—has applications in the development of a wide variety of materials and products, including semiconductors, bulk ceramics, photovoltaics, and biomaterials. “Testing with a nanoindenter is ideal for evaluating hardness or toughness of very small or thin samples, complex shapes, individual phases of a material, and surface coatings,” Simmins explained.

According to Simmins, all of the engineering disciplines in Alfred University’s Inamori School of Engineering — materials science, ceramic, glass, electrical, biomaterials, electrical and renewable energy — will utilize the nanoindenter in instruction and research.

“Because of the broad applicability of the properties measured by nanoindentation, it can be expected that the new device will be useful across all of Alfred University’s engineering programs,” Simmins said. “It is expected that the device will be used by graduate students to conduct their research and for undergraduate students to learn about fundamental materials properties in a laboratory environment.”

“This equipment will be used to conduct various projects, involving both scientific research and those applying to industry,” said Xingwu Wang, professor of electrical engineering, who taught Byrnes when he was an undergraduate at Alfred.

David Gottfried, deputy director of the Center for Advanced Ceramic Technology, said the CACT has already garnered interest from industrial partners in New York State who can benefit from the nanoindenter and its applied research.

Representatives from Semilab planned to be on campus Wednesday, Thursday, and Friday (Nov. 8-10) to give demonstrations and provide training on the IND-1500 nanoindenter. The equipment will be on loan to the University for a year, with an option to extend the loan.